Products and services

Broaching

Broach tool re-sharpening

New broach tooling

Spline Gauges

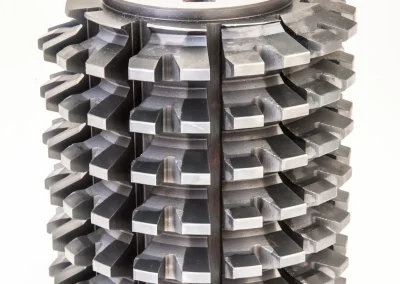

Tooling for gear production

In our production facilities, we specialize in:

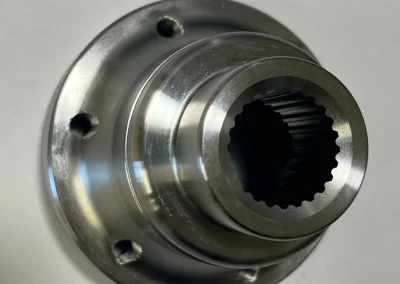

Broaching - internal spline production

We offer the broaching operation either on semi-finished components supplied by the customer, or we deliver completely machined parts including material.

Machine park – horizontal and vertical broaching machines:

-

LAPOINTE

-

Karl Klink

-

Khemka

-

7B55

Pulling force of broaching machines 10 – 15t

Max. possible length of broaching tools 2000 mm.

Broach tool re-sharpening

We offer professional and high-quality:

Re-sharpening of the broach tooling with a round profile up to a diameter of 150 mm, max.broach tool length 2000 mm.

Sharpening of keyway broaches up to a width of 60 mm, max. broach tool length 2000 mm.

Machine park – Broach tool resharpening machines:

-

Arthur Klink RSH 2000

-

Cincinnati 2000

-

Cincinnati 1500

-

Cincinnati 1000

-

Oswald Forst SM1500

-

Cincinnati 22BS

In cooperation with our proven and high-quality suppliers, we offer:

New broaching tools

High quality, long life pull and push type broaching tools with for the production of internal and external broaching for the following profiles:

- single-spline and multi-spline profiles

- involute spline

- serration spline

- keyway tools

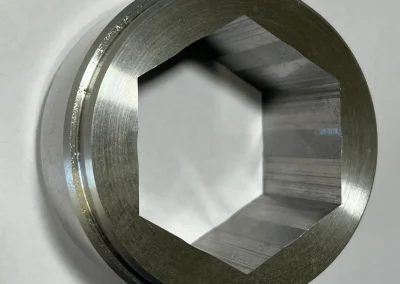

- square, hexagonal and polygonal profiles

- calibration tools

- polygon shape profile

- spiral design broaches

- special Full Form profiles

We have a very skilled design department able to design the tooling according to the needs of the customer and his machine park so that the spline production is as economical as possible (minimum number of tool passes) and at the same time the life of the tool is as long as possible.

We have been using these tools for years not only for our own production, but also supplying them repeatedly to many other engineering companies engaged in the production of parts for the automotive, aerospace and other industries in the EU.

Spline gauges and Mandrels

-

Plug gauges – Involute, serration, straight sided, parallel and tapered.

Manufacturing range: Dia 4 – 350mm, Module 0,3 – 12,0

-

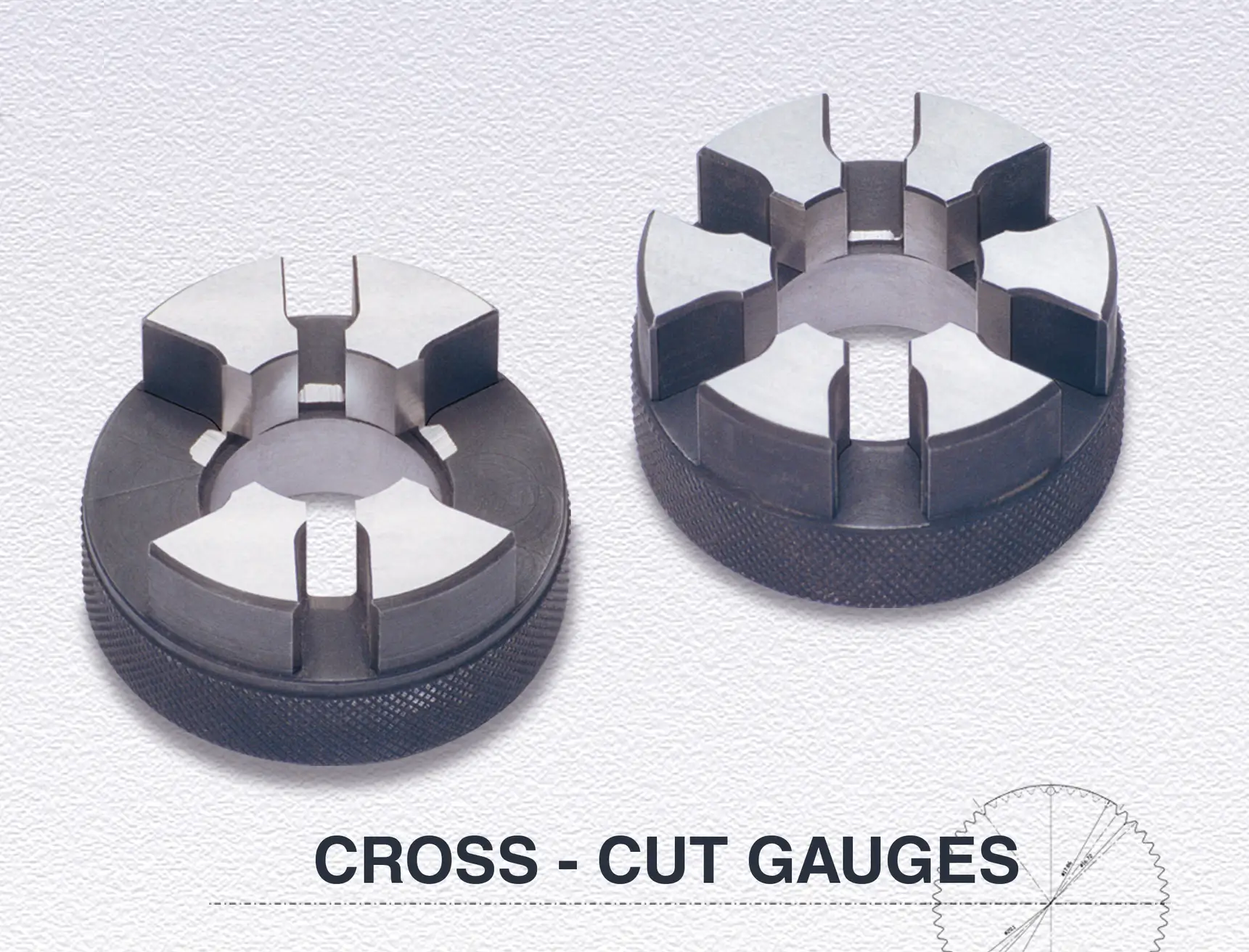

Ring gauges – Involute, serration, straight sided, cross cut, parallel or tapered,

Master plug gauge for wear control

Manufacturing range: Dia 6 – 120mm, Module 0,3 – 4,0 -

Spline turning mandrel

-

Runout checking mandrel

-

Master taper mandrel

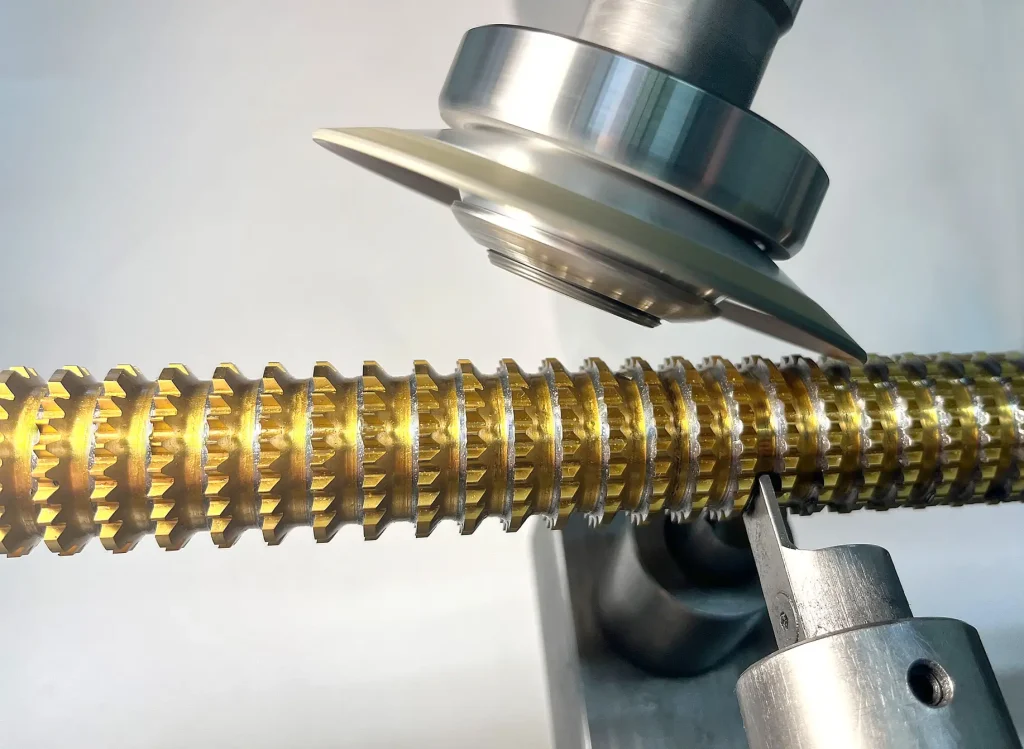

Gear production tooling

-

Gear Hobs, m 0,3 – 27, max. dia 320mm, mat. M35, ASP2030, S390, ASP2052, S290, ASP2060, Accuracy Class upto AAA as per DIN3968

-

ES-Cut Hobs for high speed wet and dry cutting up to m=7, Time Saving Up To 76%, Life Increase Up To 191% – material – type very similar to Speedcore

-

ES-H Cut Hobs for high speed cutting from m=5,5 – type material very similar to Speedcore

-

Chain Sprocket Hobs

-

Parallel or Straight Spline Hobs

-

Serration Hobs

-

Worm Gear Hobs

-

Gear Shaving Cutters, m 1,25 – 8, PCD 150 – 300mm, Thickness up to 65mm, mat. M2, M3, ASP2023

-

Rack Milling Cutters, m 0,5 – 25, Dia. 50 – 90mm, Accuracy Class upto AAA, mat. M35, ASP2030, ASP2052, S390

-

Bandsaw Cutters, Range 4TPI to 24TPI, Also made in Staggered Teeth Type

-

Worm Milling Cutters for cutting Worm Shaft, upto m 25, Accuracy Class upto AA, mat. M35, ASP2030, ASP2052 a S390

-

Form Milling Cutters for any kind of special profile

-

Rotary Cutters for cutting Straight Bevel Gears, made for G104 & G102, in T and U types, mat. M2, ASP2023

-

Spline Rolles used for cutting involute shafts and splines

-

Master Gears, m 1,0 – 8, Thickness upto 80mm, PCD 75 – 200mm, Accuracy Class IV as per DIN3962

-

Shaper Cutters, Spur & Helical Type, For Internal & External gears, m 0,5 – 10, PCD 40 -250 for Disc & Hub type, Accuracy Class AA & A as per DIN1829, mat.M35, ASP2030, ASP2052, S390

We repeatedly supply these tools to many engineering companies engaged in the production of parts for the automotive, aerospace and other industries in the EU.

If interested, we also offer a complete service including sharpening and coating.